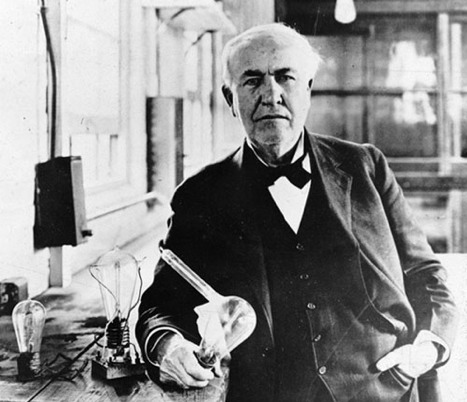

Thomas Edison did not invent the first electric light bulb.

Instead, he just solved the production and distribution problems of the existing invention. He just made a few simple changes, then he was able to make the first commercially viable electric light bulb.

Well that’s not entirely true

He tried and failed many times to find out 9999 ways “how not to make a light bulb”. Then he found one revolutionary way of how to actually make one and most importantly…

how to commercialise it.

We’ve all heard this story about how he failed 9999 times before finally creating the solution. After years of concentrated effort and failure he created one of most groundbreaking innovations of all time.

While his story of his laborious trial and error is inspirational and endorses the virtue of perseverance… it still only shows half the equation of Edison’s success.

So what lead to the mass spread of Edison’s technology? Edison understood something that many inventors under value. Edison understood the two acts required for innovation.

Invention and… Distribution

He understood that to invent an electric lightbulb was only half the work required. He instead focused his efforts on creating a commercial solution. Then, setting up the necessary systems to enable manufacture, storage and delivery he was able to see his technology used on a wide scale. He knew that distribution was equally important as the invention itself.

So what does this mean for the technology inventors and innovators of today?

If distribution is so important what can we do to use it to our advantage and gain traction in the market place? Well every business has different needs, but luckily there is a useful management tool that remains useful for all businesses. I’m going to introduce the concept of Supply Chain Management (SCM) and explain what it means if you are an innovator.

An into to SCM – supply chain management

First, what is a supply chain? A supply chain is a system of organisations, people, activities, information, and resources. This system is the process of moving a product from supplier all the way to consumption.

Now on to supply chain MANAGEMENT…

Yup you guessed it. It’s managing this system.

In short, supply chain management is the management of the flow of goods. Managing this flow of raw materials, to product, to storage, to delivery and finally consumption. Managing this flow involves going back up the supply chain and maximising the efficiency of each contributing channel.

Marketers think of the input of each channel in terms of value added to the final product. Value is used here to describe usefulness for the end user. For example if product involves shipping or warehousing then the usefulness of this function is then estimated in terms of the channels value added. If it’s something like chilled foods then refrigeration would be more important than it for a solar panel. So to maximise the efficiency of a channel: decisions must be made to evaluate which channel option offers the highest value and, adds for the lowest cost to the cost of production.

If it sounds complicated, its really not.

SCM is actually very similar to engineering systems where the aim is to maximise the output of a system whilst minimising waste in terms of energy and resources. The same goes for each channel in the distribution system.

So supply chain management is a fancy term to describe making things more productive and cost efficient from manufacture to the final distribution.

Now we know what it is, how can we improve our distribution?

Here are 3 steps to using supply chain management

- Become aware: be aware of the effects of each channel in your distribution. Are their some dodgy shipping or warehousing contractors that could be replaced? What’s the true cost of outsourcing your customer service centre?

- Think in terms of value: Is the cheapest option best for your product? Does a more expensive supplier meet more of your distribution requirements and needs?

- Monitor and review: review the outputs of each channel and monitor whether or not they meet your distribution needs. And if they do meet your needs, can you get the service cheaper elsewhere?

The most important thing is to think of the cost and value payoffs. Cheapest may not be the most effective for your business. Distribution is a key factor if innovation that can make or break businesses regardless of how innovative a product maybe.

You may need to consider…

- Is your technology fragile at certain stages of manufacture?

- Do you all the intermediaries respect your agreements?

- Are there cheaper channels to consider that will still meet your needs?

Invention is something to celebrate. But it’s not the whole equation. Successful innovation needs to be design focused for distribution. Effective distribution systems can help a project go to market and spread like wildfire. Focus on SCM and use your channels effectively. Remember to be unforgiving if channels are under performing because this means that you business as a whole is compromised.

What distribution decisions do you need to make to ensure your product makes it to the market and thrives?

Become an ECO founder

Start the 30 day ECO founder Challenge (it’s free!) to learn how to startup your own clean technology business.

No spam, ever. You can unsubscribe at anytime.

Pingback: Go-to-Market: 6 Steps Cleantech Marketing - Eco Founder()

Pingback: The Secret Habit of Successful Startup Founders - Eco Founder()

Pingback: How to become a Magnet for Sustainable Innovations - Eco Founder()